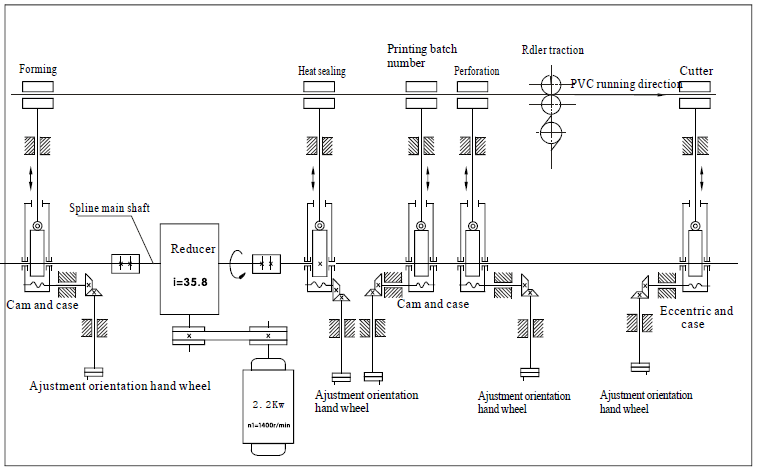

DPP260 Blister Machine drive principle

DPP series Blister Machine drive principle

The Blister Machine’s reducer is dragged by main motor and it makes spline main shaft running, Forming cam, heat sealing cam, printing batch number cam, perforation cam and cutter eccentric wheel all install on the spline main shaft separately. Each cam(cutter station is eccentric wheel) impulses each working station up and down

running to finish the forming, heat sealing, printing batch number,perforation and cutting process for the packing materials. Each working station of the Blister Machine can adjust left or right positi on through the relevant adjustment orientation hand wheel except heat sealing working station.

The purpose is to insure that the mould of each working station is consistent with the blister or the pallet position.

The roller dragging length mechanism of this type of Blister Machine is droved by servo motor.

The general working principle of the Blister Machine as following: While each working station cam rise, the mould close. And the mould of each working station finish forming,heat sealing, printing batch number, perforation and cutting progress for the materials. At this time, the dragging length mechanism stop. While each working station cam decline, the mould open. At this time the dragging length mechanism begin to drag the materials till the end position. Then each woring station can rise again,The Blister Machine go round and round like this.

DPP series Blister Machine driving system