DPH series Blister Packaging Machine forming traction length

The traction length of blister forming

1, In this type of Blister Packaging Machine, the forming area is much larger than the DPP series platen sealing Blister Packaging Machine, the speed of the cutting station is much faster than the DPP series platen sealing Blister Packaging Machine; The traction length between the forming station and cuuting station is different. To set the traction length of forming we need know the multiple between the forming mold and the cutting mold (means the speed ratio between the forming and cutting station), the smaller the blister size is, the larger the speed ratio will be, usually is 1:2, 1:3, 1:4, that means the forming station runs 1 time, the cutting station will runs 2, 3 or 4 times respectively.

Let us illustrates the calculation way of the forming traction length for a blister size that is 57 x 80mm, for this size, the multiple between the forming and cutting station normally will be 1:4, as the figure1 shows.

1) The forming station output is 12 blister cards/time, the cutting station output will be 3 blister cards/time, thus the traction length of the forming should be: (57+1) x 4 = 232mm, because the waste material usually is 1mm during cutting, so here need to add 1 mm. Then to input this 232mm through the HMI and try operates the forming station to form some blisters.

2) The forming station formed 4 rows of blister cards per time, the distance between the 1, 2, 3, and 4 blister cards is depend on the forming mold, it is fixed, can not be adjusted, here we name this distance as A.

The distance between 4 and 5 blister cards can be adjusted by the forming traction mechanism through HMI, here we name it as B.

During adjusting we must make the distance B is same as A.

3) Measure A and B by caliper. If B < A, it means the traction length is not enough, need to increase it through HMI, if B > A, it means the traction length is too big, need to reduce it through HMI. B must as same as A, otherwise the blisters can not enter into the sealing mold properly.

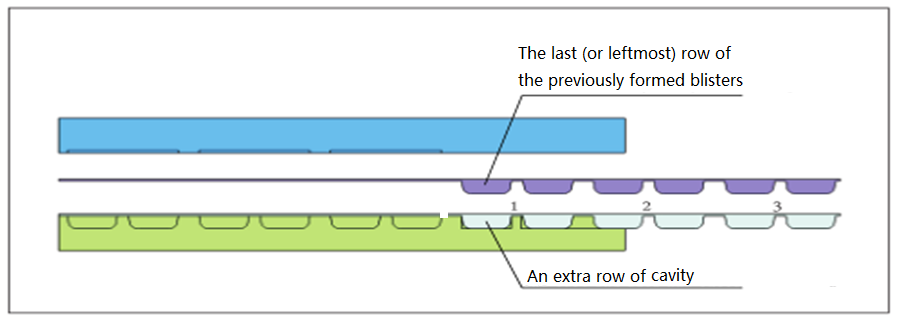

4) In order to test if the forming traction length is correct, we added an extra row of cavities at the rightmost of the lower forming mold, see the figure2.1. During forming operation the formed blisters move forward intermittently, when the upper and lower forming mold closed if the last (or leftmost) row of the previously formed blisters can enter into this rightmost cavities correctly, it means the forming traction length is correct, otherwise the forming traction length is wrong, see the figure2.2

DPH series Blister Machine forming traction length setting schematic diagram

Figure1

.png)

Forming web

Figure2.1

.png)

Forming mould

Figure2.2

Forming mould