A Blister Card Stacking and Arrangement Device

Blister packaging machines are key equipment for automated pharmaceutical packaging, particularly for solid dosage forms such as capsules and tablets. This article describes a device for stacking and arranging blister cards, transferring them from a clean area to a non-clean area. This device allows blister cards to be neatly arranged on a conveyor belt and transported in an orderly manner from the clean area to the non-clean area for subsequent packaging.

When a blister machine is used as a standalone unit (not connected to a cartoning machine in a blister line), the blister cards produced by the blister machine need to be transported from the clean area to the non-clean area (typically automatically). A common problem in actual production is that the air pressure in the clean area is higher than that in the non-clean area. This pressure differential often causes blister cards to flip over during transport, preventing them from being automatically stacked and arranged, which can cause significant inconvenience for operators in the non-clean area.

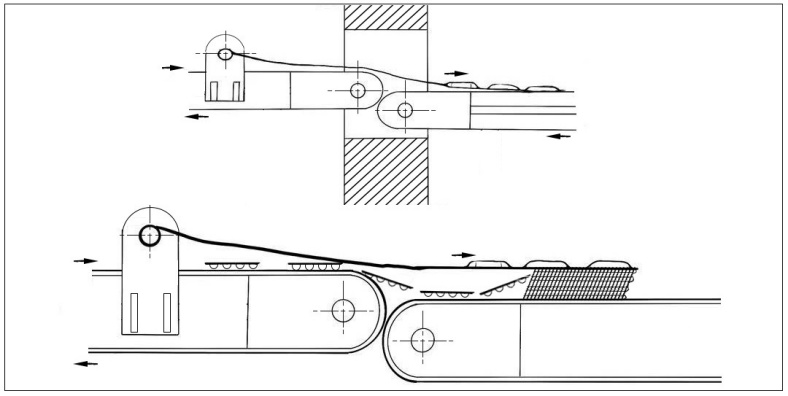

The solution to this problem is to design a conveyor belt system consisting of two straight conveyor belts. Conveyor Belt 1 is installed in the clean area, while Conveyor Belt 2 is installed in the non-clean area. The end of Conveyor Belt 1 and the front of Conveyor Belt 2 are located at the opening in the partition wall between the clean and non-clean areas, and are closely connected. Conveyor Belt 1 is higher than Conveyor Belt 2 in terms of height. A flexible sheet is installed above Conveyor Belt 1 and Conveyor Belt 2, extending from Conveyor Belt 1 through the opening in the partition wall to the top surface of Conveyor Belt 2. A counterweight is placed at a distance from the flexible sheet on the surface of Conveyor Belt 2. During production, blister cards punched by the blister packaging machine are neatly placed on Conveyor Belt 1 in the clean area and then conveyed to Conveyor Belt 2. Because Conveyor Belt 2 runs at a lower speed than Conveyor Belt 1, the blister cards are stacked and transported on Conveyor Belt 2. The flexible sheet installed at the opening in the partition wall holds the blister cards in place on the belt, preventing the stacked cards from being blown apart by the pressure difference between the two areas. The counterweight presses the flexible plastic sheets, preventing them from floating and causing poor sorting.

This device enables the Blister Card to be smoothly transported and stacked, making it easier for personnel in non-clean areas to retrieve and enter the subsequent packaging process, thereby significantly improving work efficiency.

A schematic diagram of the device is shown below: