A line combined with Pillow-packing, Cartoning, and Stretch-Banding

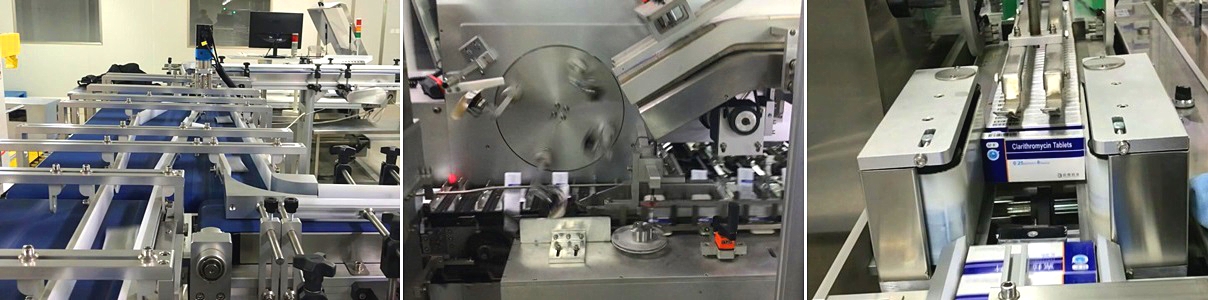

Recently Jornen provided a packaging line to a pharma; this line combined with pillow-packing, cartoning, weigher, ink-jet printer, and Stretch-Banding.

The blister cards are loaded inside a magazine; the blister cards are counted when they free fall via the servo-regulated system to the transfer chain. The transfer chain moves the blister cards to the pillow-packing unit. After pillow-packing, the blister cards are discharged to the transfer belt; while driving on the way, a rake guides the blister cards into two lanes from there, they continue into the feeder of the cartooning machine.

In the cartooning machine, the servo-regulated feeder placed the blister cards in the transfer chain; The chain drives the blister cards forward and the cartooning machine automatically finished the action of leaflets folding, carton opening, blister cards inserting, embossing, tuck-in, or hot-melt closures, and carton discharging.

After cartooning, the weigher checked the products; reject the faulty products automatically;

This line adopts an ink-jet printer for cartons. The printer can print variable data such as date/lot codes and serialization barcodes. The printing codes’ legibility is much more excellent than die embossing.

After printing, the cartons move forward to the Stretch-Banding unit; two soft belts turn the carton 90 degrees and grouped them into a larger unit. These units are then tightly wrapped in plastic film

The video of this line is available at:

https://youtu.be/_3vF2voK3FA

cartoning machine