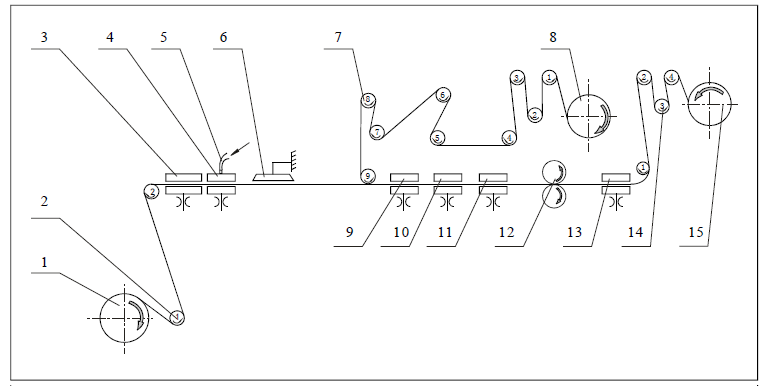

DPP260 Blister Machine working principle

DPP series Blister Machine working principle:

Blister Machine forming material normally is PVC film 1 and lidding foil normally is Alu foil 8 are dragged into each work position intermittently by roller traction mechanism12.

Firstly, Forming material (PVC) 1 go through forming turn stick 2 come into forming heat plate 3 . Then the material which has been come into the forming station 4. is extended and formed blister by the compressed air 5. When the blister come into feeding device 6, it will be filled with medicines. Then it will come into heat sealing position 9.

Alu foil 8 through the alu turn stick 7 enter the heat sealing position 9. Here PVC and ALU are bonded and the medicines are sealed in the blister. Then enter into the embossing position 10 to emboss production batch number. And enter the perforation working station 11 to perforate the peel line.

Finally it enteres the cutter working station 13 and is cut into blister card. The rest material will be collected by waste winding mechanism 15 through

the waste winding turn stick 14. In this series Blister Packaging Machine every working position worked in synchronized way.

DPP series Blister Machine schematic diagram:

- Blister Machine forming material(PVC)

- Forming turn stick

- Forming heat plate

- Blister Machine forming station

- Compressed air

- Feeding device

- Alu foil turn stick

- Alu foil

- Blister Machine heat sealing station

- Blister Machine embossing station

- Blister Machine perforation station

- Traction mechanism

- Blister Machine cutter working station

- Turn stick of waste winding

- Waste winding mechanism