Blistering and cartoning solution for vials or ampoules

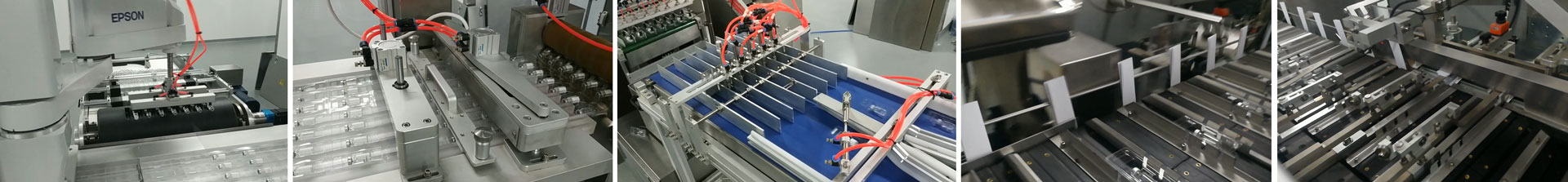

This is a blistering and cartoning solution for vials or ampoules. The Blister Line contains a Blister Machine and Cartoning Machine, the blister machine equipped a servo-regulated robot feeder for vials. In this feeder, a conveyor transports the vials into the tracks. A motor driven slide distributes the vials evenly. A rake guides the vials into the chutes and forms them into lines; from there they continue into the slots of a servo-regulated roller. The servo driven roller turns 90 degrees, moving the vials into a horizontal position. The vials are then collected by the robot with vacuum suction cups from the slots of the roller, and accurately and gently placed into the formed web. The blister pocket adopts clamp-packs unique design: The press-in station gently pushes the vials into the pockets to ensure the vials are firmly clamped in the pockets; preventing products from falling from the pockets, thinks to this unique design, this vials blister packaging no longer need the lidding material, thus there is no sealing station in this blister machine.

After the blister packs were punched and discharged, there is another robot to collects and places them on a conveyor, the conveyor transfer the blister packs towards the Cartoning Machine.

The Cartoning Machine equipped two servo-regulated turntables, from there the blister packs moves into the slots of the turntable, the turntable rotates intermittently, thinks to the servo-regulated tech, the turntable acting synchronously with the continuous motion Cartoning Machine, accurately and gently places the blister packs into the Cartoning Machine’s conveyor. At the end of the line, the cartons loaded with vials blister pack are discharged automatically.

The video of this Blister Line is available at:

https://youtu.be/x-SSPOti12Y

blistering and cartoning for vials or ampoules