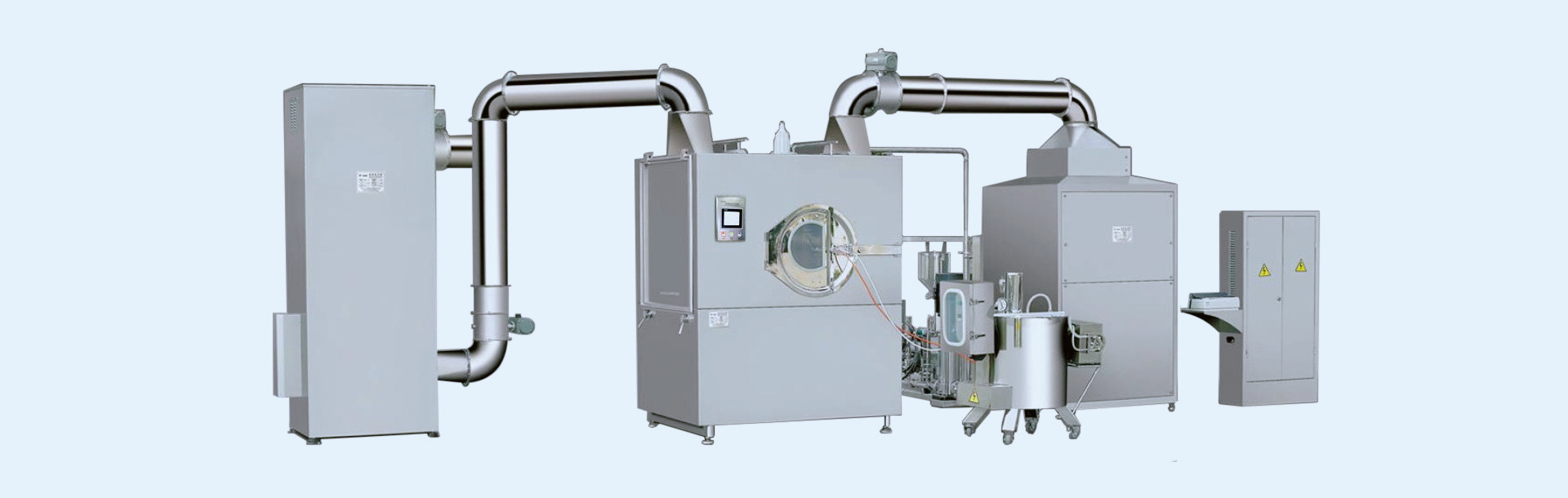

BG Film Coating Machines

The Film Coating Machine can be used for coating various tablets, pills, and sweets with organic film, water-soluble film, and sugar film, etc., in pharmaceutical, food, and biological industries. It is noted for its high efficiency, low energy consumption, and space-saving qualities.

Basic working principle:

The tablets make a continuous, complicated, orbital motion in the closed drum of the film coating machine. The mixed coating is sprayed on the tablets with the spray gun through the action of the peristaltic pump.

Meanwhile, under the action of the Air Exhaust Cabinet (creates negative pressure) and Hot Air Cabinet (supplies hot air), a 100,000 level purification of clean hot air, supplied by the Hot Air Cabinet, penetrates the tablets, and they are then exhausted from the bottom of the layers. This allows the coating medium, which is sprayed on the surface of the tablets, to dry rapidly and evenly, thus forming a solid and smooth film surface.

Characteristics:

1、All operations are integrated through HMI, providing reliable and stable performance.

2、Under the action of a streamlined guide plate, the tablets tumble frequently and smoothly, thus preventing them from falling from a high place and colliding. This prevents broken pieces and chipped edges and improves the qualification rate of the finished products. The narrow surface of the guide plate eliminates the adhesion of coating material on its surface, thus conserving coating material.

3、An automatic, high-efficiency feeding device prevents cross pollution.

4、Automatic cleaning system: The coating drum equipped in the high-pressure washing gun is used for cleaning the air exhaust outlet and hot air inlet and can be rotated in automatic and full direction, leaving no recesses or hidden corners where dust can hide (Optional).

5、Selecting the international top-grade spray gun allows the flow and angle of the sector to be adjusted, providing a no leak, straightforward operation. The spray gun requires a certain level of air pressure for opening to avoid leaking and wasting of coating materials.

6、A special mechanical device provides the machine with great flexibility, allowing it to handle even very small batches (coat 20kg pills in 150 type coating machine).

|

Items/Model

|

BG600E

|

BG400E

|

BG150E

|

BG80E

|

BG40E

|

BG10E

|

BG5E

|

|

|

Load Capacity

|

600 Kg

|

400 Kg

|

150 Kg

|

80 Kg

|

40 Kg

|

10 Kg

|

5Kg

|

|

|

Revolutions (r/min)

|

1.0-12r/m

|

1.0-13r/m

|

1.0-16r/m

|

1.0-19 r/m

|

1.0-21 r/m

|

1.0-25 r/m

|

1.0-30 r/m

|

|

|

Major Machine Power

|

4Kw

|

3Kw

|

2.2 Kw

|

1.5 Kw

|

1.1 Kw

|

0.55 Kw

|

0.37 Kw

|

|

|

Size of Coating Drum

|

Φ1580mm

|

Φ1580mm

|

Φ1200mm

|

Φ930mm

|

Φ780mm

|

Φ500mm

|

Φ564mm

|

|

|

Power of Air Exhaust Cabinet Motor

|

11 Kw

|

7.5 Kw

|

5.5 Kw

|

3 Kw

|

2.2 Kw

|

0.75 Kw

|

0.55 Kw

|

|

|

Air Exhaust Flow

|

15450 m3/h

|

10000m3/h

|

7419 m3/h

|

5268 m3/h

|

3517 m3/h

|

1285 m3/h

|

805 m3/h

|

|

|

Power of Hot Air Cabinet Motor

|

4 Kw

|

2.2 Kw

|

1.5 Kw

|

1.1 Kw

|

0.75 Kw

|

0.37 Kw

|

0.25 Kw

|

|

|

Hot Air Flow

|

6500 m3/h

|

3517 m3/h

|

2356 m3/h

|

1685 m3/h

|

1285 m3/h

|

816 m3/h

|

504 m3/h

|

|

|

Major Machine Weight

|

1600 Kg

|

1000 Kg

|

850 Kg

|

600 Kg

|

500 Kg

|

200 Kg

|

750Kg

|

|

|

Air

|

Pressure

|

≥0.4Mpa

|

≥0.4Mpa

|

≥0.4Mpa

|

≥0.4Mpa

|

≥0.4Mpa

|

≥0.4Mpa

|

≥0.4Mpa

|

|

Air Consumption

|

2 m3/min

|

1.5 m3/min

|

0.7 m3/min

|

0.35 m3/min

|

0.2 m3/min

|

0.2 m3/min

|

0.2 m3/mi

|

|