Brief Description of pinhole detection in Blister Pack

Medicine packed in blister machine has different requirements for barrier for water and oxygen. Alu-alu blister pack is typically used for medicines requiring excellent barrier properties. The moisture vapor transmittance (MVTR) of alu-alu blister packs is virtually zero, nearly complete barrier for water and oxygen.

Alu-alu blister pack adopts aluminum-based laminate film as the forming material, in the blister machine’s forming station, aluminum film is simply pressed into a mold by means of a stamp. The aluminum will be elongated and maintain the formed shape. In the industry these blisters are called cold form foil (CFF) blisters. With the improvement of aluminum foil rolling technique and control accuracy, aluminum foils with thickness of more than 20-25 Micron can be considered as having no pinholes and fractures. But aluminum films are vulnerable to cracks when going through the elongation forming process on the blister packaging machine; or even if aluminum films are free of fractures, they may have tiny pores that are invisible to the naked eye, with a typical diameter of less than 100 Micron (human hair generally has a diameter of about 60-70 Micron), which is known as pinholes. That means the barrier property of aluminum blister packs is damaged, thus impairing the impermeability of pharmaceuticals. How to detect and reject blister cards with pinholes (regards it as a faulty blister card) to guarantee their sealing performance? Blister packaging machine equipped with online pinhole detectors is the answer.

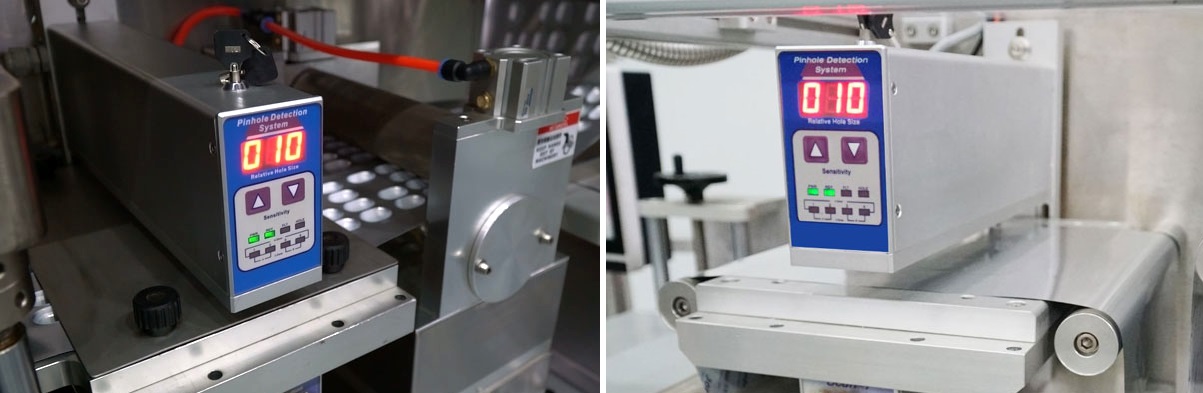

The pinhole detector is equipped with a light emitter to transmit light (far infrared light) that covers the width of the cold-formed aluminum film on the blister packaging machine, and a highly sensitive light receiver beneath the aluminum film. The pinhole is installed after the blister machine’s forming station, after forming, the cold formed web moves through the pinhole detector, if the aluminum film is free of cracks and pinholes, the light receiver will not receive any light; and the system displays the accuracy in digits and the green light is on, indicating that no pinhole is detected in the material under such detection accuracy, and that the barrier property of the aluminum blister pack is assured. If the cold-formed blister film is invaded by cracks or (even without cracks) hairlike pinholes (of (50-100 Micron thick) due to unreasonable mold design, over-stretching or defective formed film, the light receiver will receive the light passing through the aluminum foil and measure the size of the pinholes; if the size of the pinholes is greater than the preset detection sensitivity, the system sends a red light signal indicating that there are cracks or pinholes and the barrier property of the material is damaged. At the same time, the system sends a signal to the blister packaging machine prompting the necessity to take corrective measures for the blister card with cracks or pinholes. For example, stop feeding the faulty blister card, reject it after punching, and make corresponding records on the production line. The pinhole detector can detect pinholes with diameter of 10 Micron, with 6 levels of sensitivity configurable including 10, 25, 35, 50, 70, 100 Micron.

As a manufacturer of the blister packaging machine, offering perfect and flawless blister packs is our responsibility and also an important link of drug safety.

Jornen Machinery

04-12-2019