DPH series Blister Machine-the punching station

DPH series Blister Machine Punching Station

In the Blister Machine, in the punching station, blister cards are punched out of the formed and sealed web during dwell time of the multiple-stroke index. During punching, the web is fixed in position between the convex and concave die. The convex dies press into concave die, thus punching the blister cards out of the formed and sealed web.

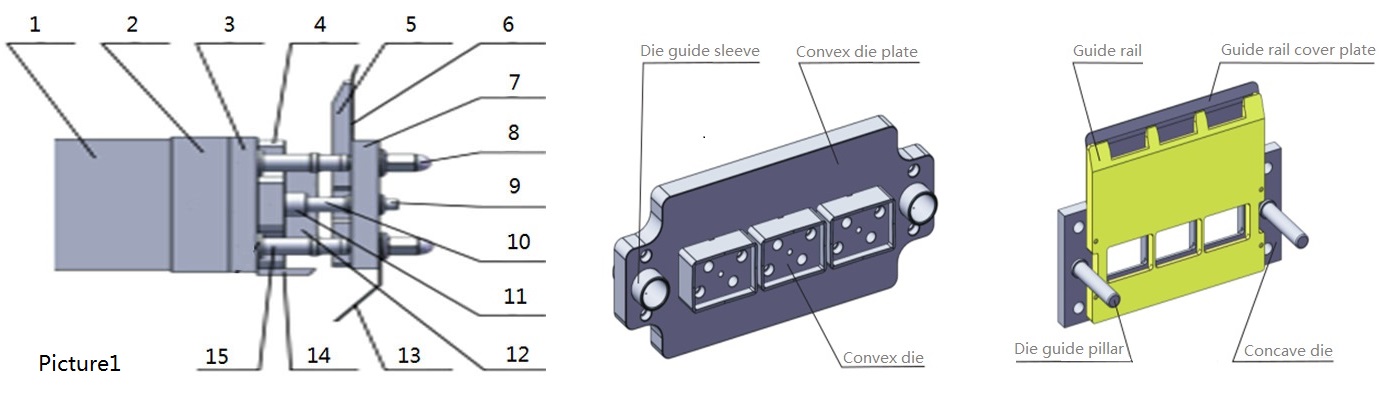

Punching station diagram and parts name.

Blister Machine punching die

1. Punching Box 2. Protective Cover 3. Punching Guide Plate 4. Convex Die Plate 5. Guide Rail 6. Guide Rail Cover Plate 7. Concave Die 8. Ball Head Nut 9. Screw 10. Die Guide Pillar 11. Die Guide Sleeve 12. Convex Die 13. Waste Material Plate 14. Waste Material Knife 15. punching Station Pillar

Replacement of the punching die

To replace the punching die, we must to power off the Blister Machine for safety.

Remove the old one:

Remove the four ball head nut (8); Take out the concave die (7), the guide rail (5) and the die guide pillar (10); Take out the screws on the convex die plate (4) and take out the convex die plate.

Install the new one:

Install the convex die plate (4) to punching guide plate (3) but do not firmly fasten the screw; Install the concave die (7) to the four punching station pillars (15), let the die guide pillar (10) enter into the die guide sleeve (11); Fasten the convex die plate to the punching guide plate firmly then fasten the ball head nut firmly.

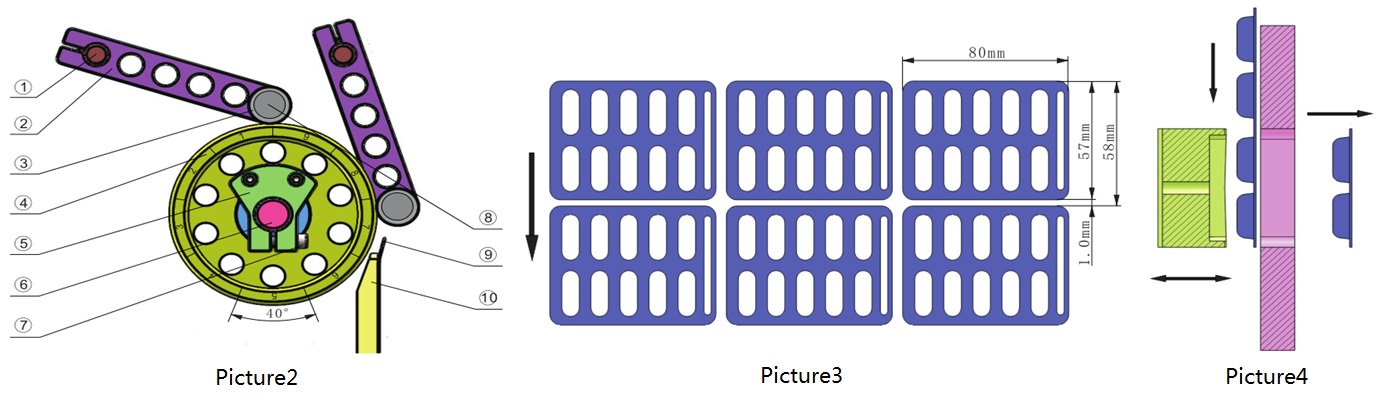

The Working Principle of the Punching Index

Push the handle (8) and lift the swing arm (2); Pull the formed and sealed web into the punching roller index, ensure the formed blisters on the web enter into the cavities of the roller; Lay down the two swing arms to press the web to the roller index. When the Blister Machine runs, the roller index drives the web into the guide rail (10) and punching die;

The Punching Index diagram and parts name

Blister Machine punching index

1. Spring Shaft

2. Swing Arm

3. Press Roller

4. Roller Index

5. Link Block 6. Roller Axis

7. Locking Screw

8. Handle

9. Guide Rail Cover Plate 10. Guide Rail

The angel setting of roller index

Take the blister card size 80×57mm as an example, the 57mm is the size of index direction (picture 3), it means each stroke is 57mm, how many angle the roller need to turn every time?

To calculate how many blister cards around on the circumference of the roller, in this case (picture 2) shows there are 9 blister cards on the circumference; It means the roller turns 360° (one revolution) makes 9 strokes, each stroke is: 360°÷9=40°; To set this angle number through machine’s MHI, the setting of the angle is very important, if set wrong data the blister machine can not punch the web correctly.

After the setting, pull the formed and sealed web through the roller index to punching die, the blister cards should be punched like picture4 shows, if the position is not correct, please loosen the locking screw (7) see picture2, manually turn the roller some angle to correct the position of the web, after adjustment fasten the screw (7) again.