DPH series Blister Machine Track Feeder

Track feeder has been developed for feeding capsules and tablets in various shap such as: flat, oblong, oval tablets and capsule tablets with small bevels. It mainly consists of a hopper, vibratory chute, vibratory conveyor and grooved feeding plate. This type of feeder is mainly used to continuous motion Blister Packaging Machine, but can also be installed on the intermittent Blister Packaging Machine

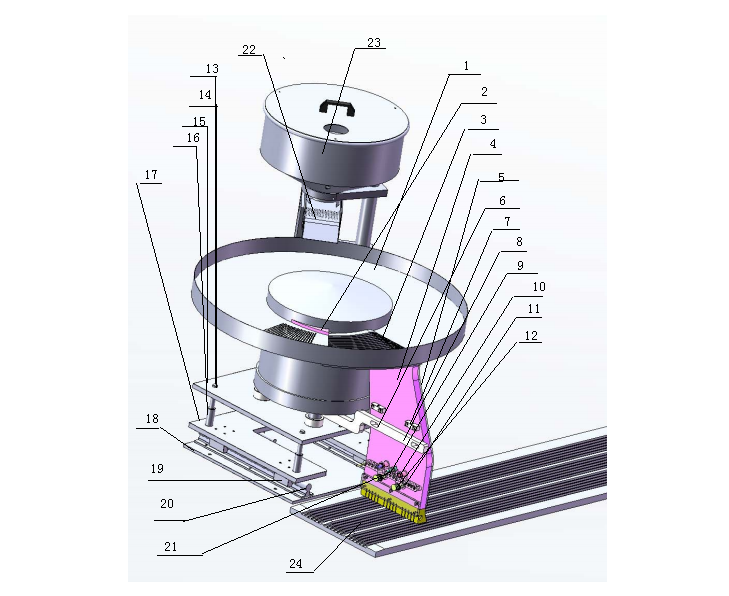

Blister feeding begins by transferring the tablets into hopper (23), they then exit the hopper via the linear vibratory conveyor (22), they fall into the disk vibratory conveyor (1), they move in circles and flow down the grooves in the feeding plate (4), the tablets fall down vertically through the grooves and finally lay down into the pockets

2. Adjusting method of the track feeder

1) Install the guide rail (24), install the feeder on the feeding area. The grooves in the feeding plate (4) should align with the grooves of guide rail (24), according to tablet size to adjust the gap between the feeding plate (4) and the guide rail (24) by the adjusting screw (7), after adjusting, fix the feeding plate on the support plate (8).

2) Adjusting the height of the upper adjusting plate (15) by upper adjusting nut (13) and lower adjusting nut (14), this height can determines the gap between the disk vibratory conveyor (1) and the feeding plate (4), different tablet size will require different gap.

3) The grooves in the slant plate (3) must align with the grooves in the feeding plate (4), to adjust the position of the lower adjusting plate (17) through the guide rod2 (19) can move the disk vibratory conveyor (1), when the position is right then fix the locking block (21).

4) Finally adjusting the left and right position between the feeding plate (4) and slant plate (3) by moving the bracket (25), after the adjusting fix the bracket .

DPH series Blister Machine Track Feeder schematic diagram:

blister machine Track feeder

1. Disk Vibratory Conveyor 2. Guide Plate 3. Slant Plate 4. Feeding Plate 5. Cover Plate 6. Lock Screw 7. Adjusting Screw 8. Support Plate 9. Feeding Control Pedestal 10. Guide Rod1 11. Spring 12. Feeding Control Peg 13. Upper Adjusting Screw Nut 14. Lower Adjusting Screw Nut 15. Upper Adjusting Plate 16. Supporting Pillar 17. Lower Adjusting Plate 18. Fixed Pedestal 19. Guide Rod2 20. Sliding Seat 21. Locking Block 22. Linear vibratory conveyor 23. Hopper 24. Guide Rail