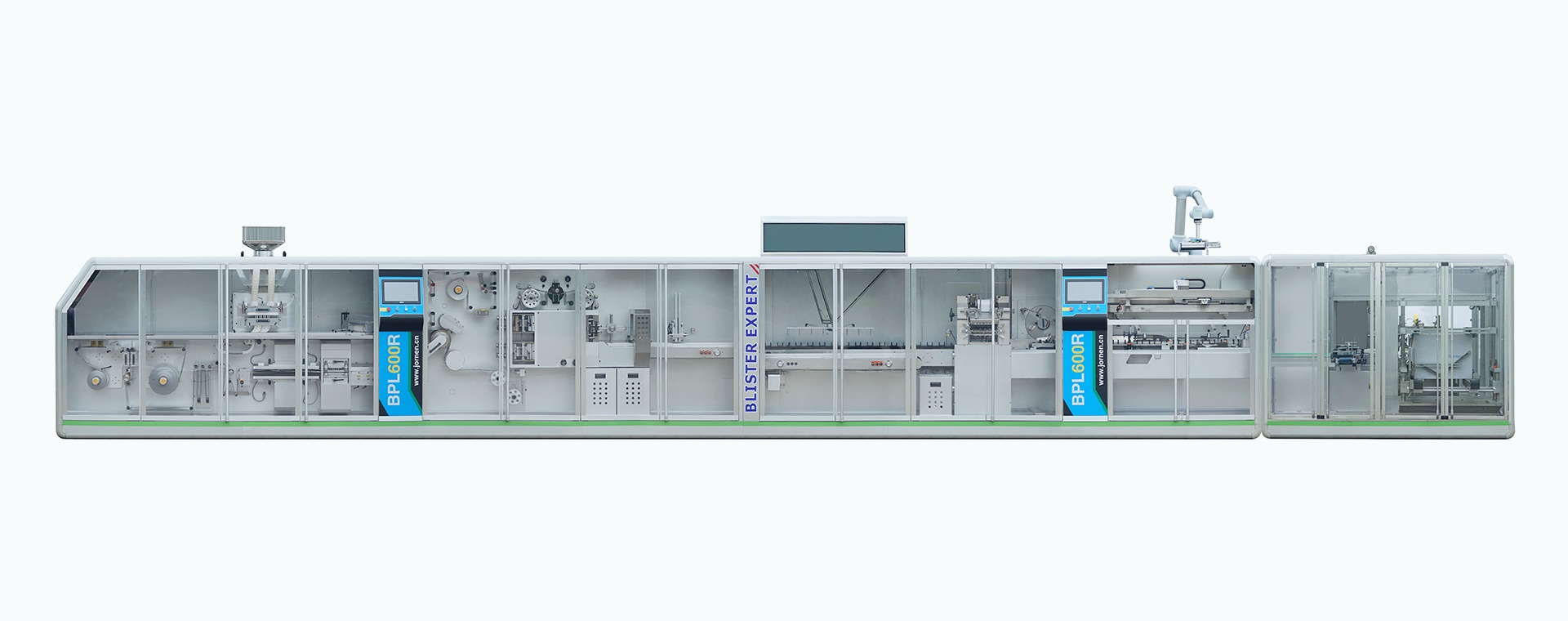

Blister Line BPL600R (Blistering/Cartoning/Case Packing))

The video of this line:

https://youtu.be/IQJN6XFPr7s

This blister packaging line consists of three units: a blistering unit, a cartoning unit, and a case packer. Maximum capacity reaches 600 cartons per minute.

The Blister unit features a cantilever structure, with the driving system fully isolated from the operating area. This makes daily maintenance and cleaning easier, prevents cross-contamination, and complies with pharmaceutical GMP requirements.

A delta robot transfers blister cards to the cartoning unit for efficient and stable packaging.

The cartoning unit is equipped with an automatic carton loading system.

After the cartoning unit, the carton is automatically stacked and transferred to the case packer. The palletizing mechanism can be configured after the case packer.

The product-inserting device in the cartoning unit is positioned at the back of the machine. This design optimizes ergonomics compared to traditional cartoning machines, where the product-inserting device is installed in the front and protrudes from the operating surface.

It boasts a uniquely enclosed design, perhaps the most elegant blister line in the world.

See our machines’ performance in the pharmaceutical company.

-1-300x300.jpg)