Blister Line BPL500P

.jpg)

The video of this line:

https://youtu.be/TLASXejQX1M

> High-speed blistering/pillow-packing/cartoning packaging line, fully servo regulated, the culmination of our more than 30 years of professional experience.

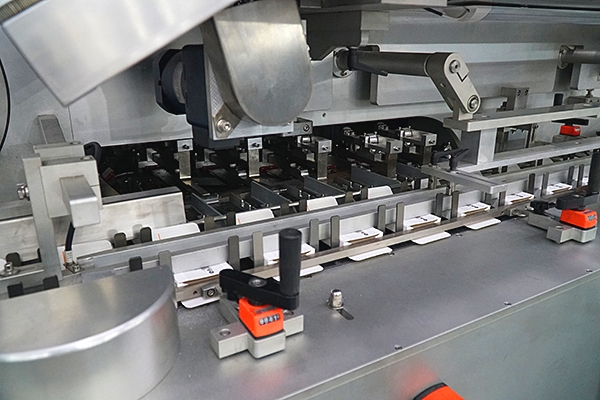

> By integrating a blistering, pillow-packing, and cartoning module for packaging pharmaceutical tablets and capsules, high efficiency and highly flexible, maximum output reaches 500carton/, it is ideal for mass production.

> Processes all common solid dose products and all types of forming material.

> GMP-compliant cantilever (balcony type) layout for easy pharmaceutically compliant cleaning.

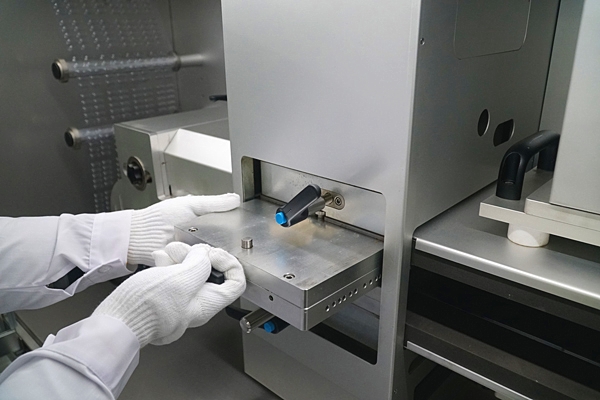

> Adopt quick plug & play format locking and positioning design, achieving straightforward format changeover.

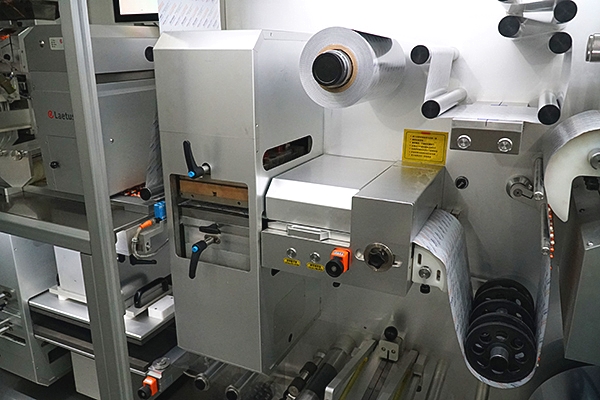

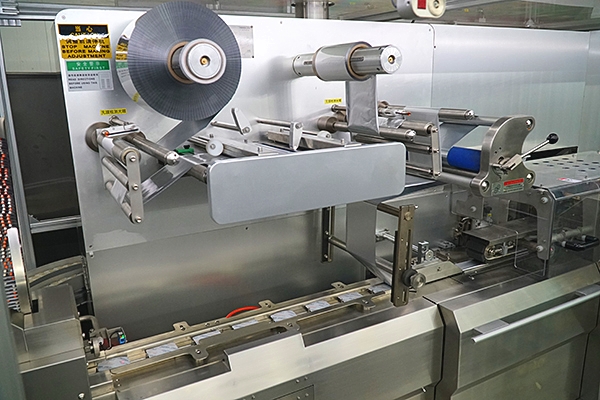

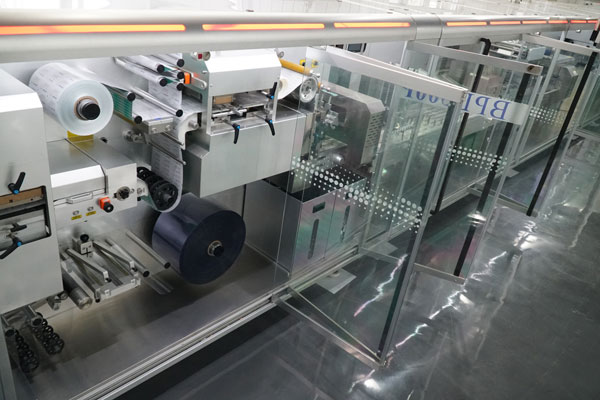

> The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and waste material trimming cutter.

> The indexing system adopts a precise servo motor to achieve stable, accurate running. The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

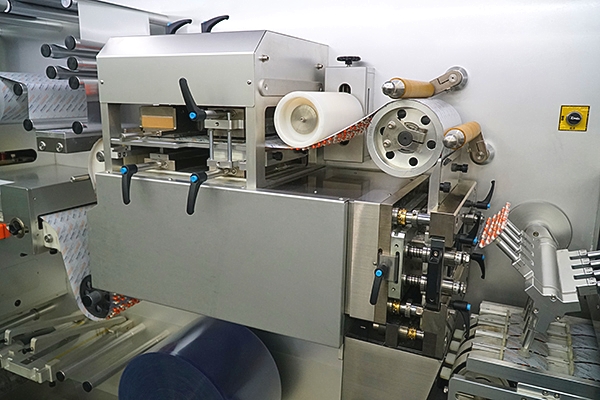

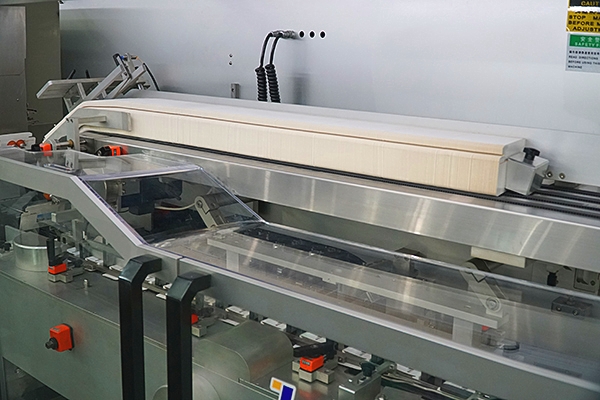

> This line integrated a pillow packing unit after the blistering unit to allow the plastic thermoforming blister package to be sealed again by a laminated film that offers a nearly complete barrier for water, light, and oxygen, allowing an extended product expiration date.

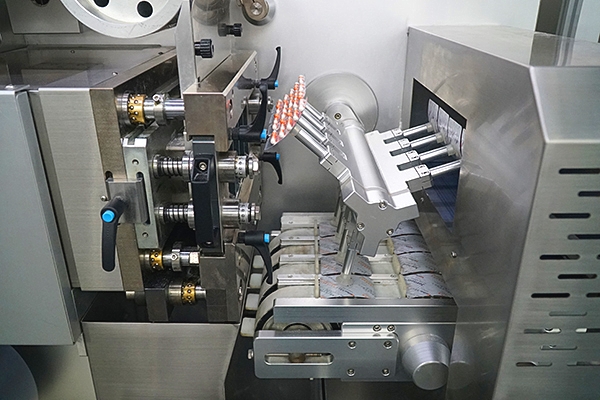

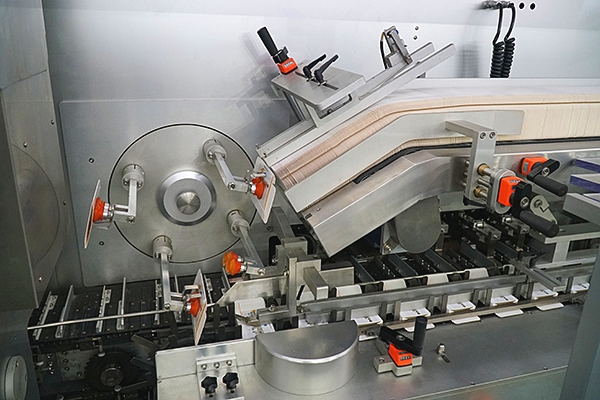

> The cartoning machine is truly ergonomic thanks to the innovative design whereby the product inserting device is placed at the rear; The conventional cartoning machine’s inserting device is placed at the front side, where it protrudes from the operation side and is less ergonomic.

> Capable of all standard types of closure systems for cartons from tuck-in to hot melt.

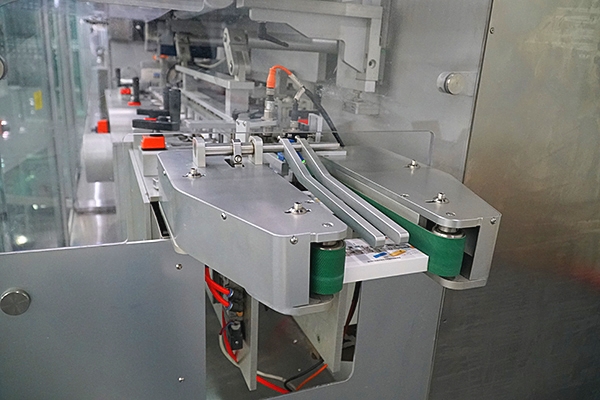

> The heart of a Blister Line is the connection unit; this line has two connection units, the unit between the blistering and pillow-packing and the unit between the pillow-packing and cartoning. Thanks to the innovative servo-regulated technology, the blister cards are transferred, positioned, and fed to pillow-pack and cartoning units accurately and synchronously. These precise controls assure the stability of high running speed.

> This line adopts the fully enclosed structure and safety door; it aligns with the stringent safety standards.

Max. Output: 500 cartons/min.

Range of Carton Size: Max.: 200x90x60mm Min.: 75x35x15mm

Machine Power: 55kw

Machine Dimension: 1650x1700x2100mm

Machine Weight: 9000kg

-1-300x300.jpg)

-300x300.jpg)