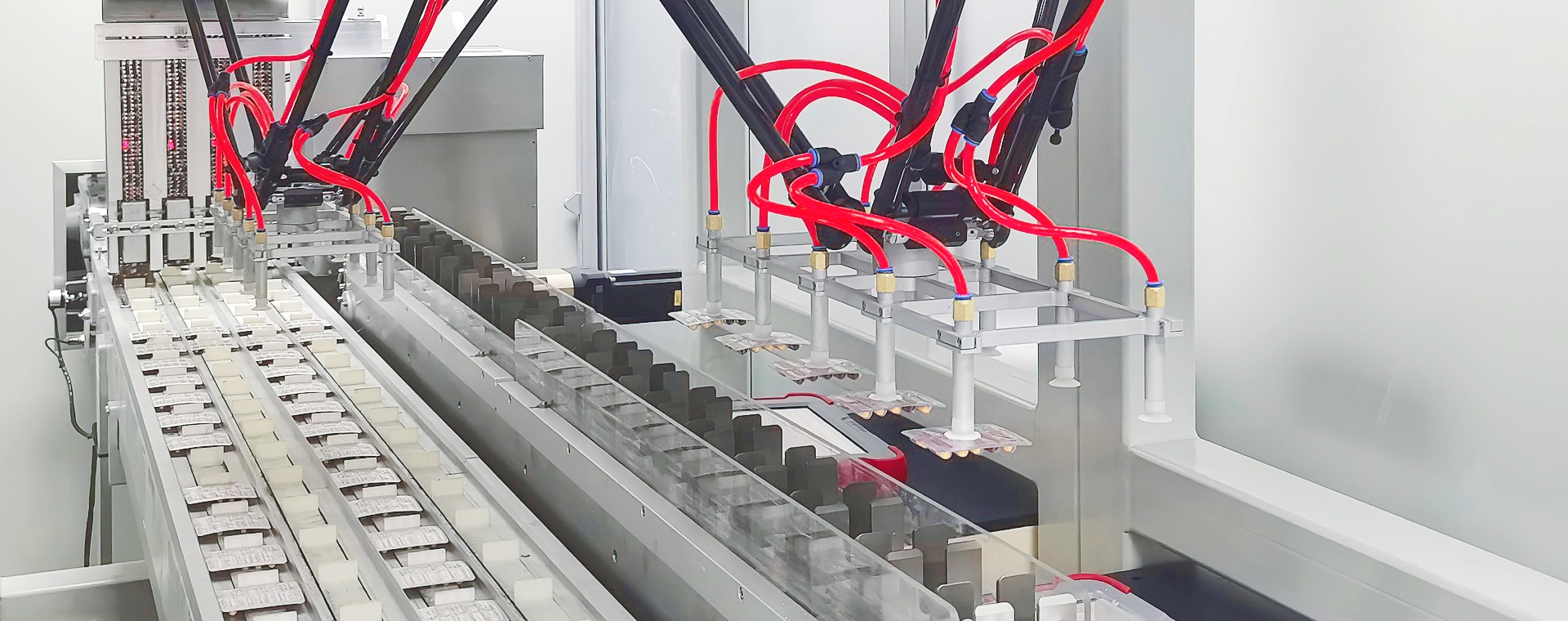

Blister Line Equipped With Delta Robots

Jornen recently provided a blister line for a pharmaceutical company that integrated different units to create a high-tech system.

This blister line included a rotary-style blister packaging unit, a delta robots connection unit, and a continuous motion cartoning unit.

The blister packaging unit used a multiple-tube feeder that could fill the entire index of the blister each time, increasing production significantly.

To achieve flexible and accurate operation, the blister line’s connection unit was equipped with two delta robots that picked up the blister cards and stacked them in the bucket.

This technology allowed for the stacking of multiple blister cards, which could then be transferred to the cartoning unit.

The cartoning unit was a continuous motion-style machine that could automatically complete the carton opening, blister card insertion, carton closure, and discharging.

The continuous motion cartoning machine’s advantage was its high speed, reducing the need for a large labor force.

Overall, the blister line provided an innovative and efficient solution for the pharmaceutical company’s packaging needs.

The videos of this bister line are available at:

https://youtu.be/XUgM4pkTIkc

https://youtu.be/2WBLyr4sfeM

-300x300.jpg)

-1-300x300.jpg)