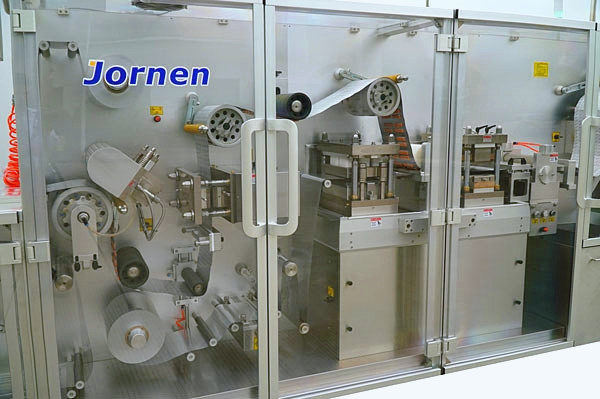

Blister Machine DPH260H3 (alu-pvc-alu)

.jpg)

Video of this machine:

https://youtu.be/hv7JlPTuaEA

According to different packaging materials and principles of forming, Blister packs may be divided into mainly two types: aluminum/plastic (thermoforming) blister pack and aluminum/aluminum (cold forming) blister pack.

The advantages of thermoforming blister pack:

> It can visually examine the product through the transparent plastic, it is easy to reject the fault blister card both by inspecting the camera or naked eyes.

> The most basic material for the forming web is PVC, it is low cost and the ease of thermoforming.

> Because the cavity or pocket contains the item snugly so it can adopt a universal feeder, it is low cost and easy of operation.

The disadvantages of thermoforming blister pack:

> The poor protective properties because of poor barrier against moisture ingress and oxygen ingress;

The advantages of cold forming blister pack:

> The use of aluminum offers a nearly complete barrier for water, light, and oxygen, allowing an extended product expiration date.

The disadvantages of the cold forming blister pack are:

> The slower speed of production compared to thermoforming;

> The lack of transparency of the package increase the difficulty for inspecting the system to reject the fault blister card;

> The larger size of the blister card (aluminum cannot be formed with near 90 degree angles), increase the cost.

> The material of forming aluminum film is more expensive than pvc.

> Because the cavity or pocket is larger than the item so the feeder should be dedicated, which increases the cost and operation difficulty.

To take the above advantage and get rid of the disadvantage, this industry launched the third type of blister pack: aluminum/plastic/aluminum blister pack.

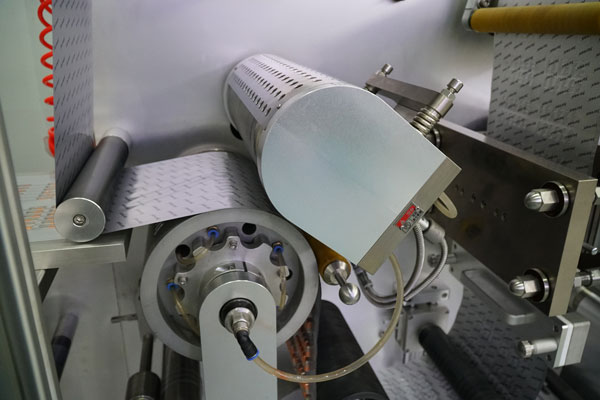

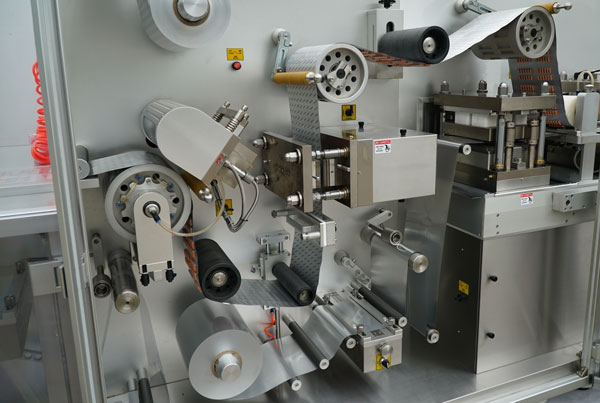

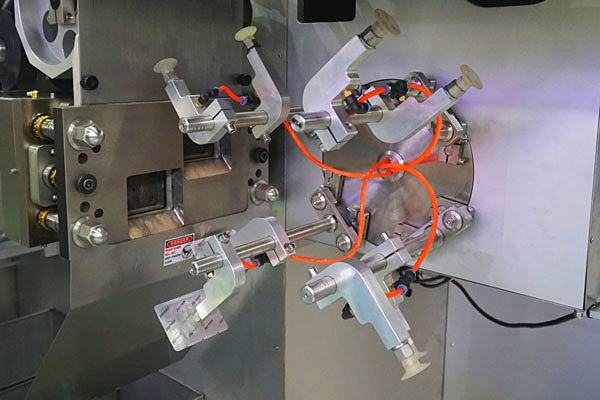

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

Because the item is filled in thermoforming pocket or cavity so it can adopt a universal feeder, it is low cost and easy of operation.

The inspecting camera can detect the fault blister card easily because of the transparency of thermoforming plastic.

Tropical aluminum has the same property as cold-forming aluminum that can offer a nearly complete barrier for water, light, and oxygen, perfectly protect the medicine.

The characteristics of Blister Packaging Machine DPH260H3

> The alu/pvc unit adopts larger forming area stating and rotary style sealing stating thus increase the speed.

> The tropical alu forming station has a larger forming area archive larger output requirement.

> The second sealing station has a larger sealing area to allow the plastic thermoforming blister package to be sealed with formed tropical alu at a higher output capacity.

> The punch station can adopt the crossing type, the trimming waste is about 1mm between two blisters; it can save more material.

> Thanks to rotary sealing style (alu-pvc) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).

DPH260H3

Max. Speed: alu/pvc/alu 105 punches/min.

Max Forming Depth: 12mm

Material: Max. width 265mm

Machine Power: 25kw

Machine Dimension: 7000×1300×2000mm

Machine Weight: 4500kg

*Note: Actual production speed is limited by tablet characteristics, feeding system, blister card size, etc.

Blister Machine BMP270-Cartoner ZH150 in pharma: https://youtu.be/UhJkh2VsQaY

Blister-cartoning line for package of vials https://youtu.be/O8RL7wSeChE

Blister Line in production in Europe https://youtu.be/crm_IKw8DhY

Solution for vials and ampoules blistering and cartoning: https://youtu.be/x-SSPOti12Y

Cartoning Machine for bottles and vials: https://youtu.be/3PyXoBpTPv0

Hot-melt cartoning for the packaging of stickpacks: https://youtu.be/W2z21cM-knM

A line of Blister Machine-Pillow Packing-Carting Machine-Overwrapper: https://youtu.be/5OGCXbCknBY

Cartoning Machine for frozen foods: https://youtu.be/4t3-s7GBZsk

Cartoning Machine for cosmetic: https://youtu.be/P_Fp12p46r4

A line integrates blistering, pillow packing, cartoning and overwrapping: https://youtu.be/YLv7Yn8Q-ts

Blister Line integrated blister card inspection system: https://youtu.be/6Pvi_hwXt6s

Blister Packaging line in pharma: https://youtu.be/ZWBIlqgVHsU

High Speed Blister Machine equipped pinhole detection system: https://youtu.be/81PgXpAMVsU

Intermittent Blister Packaging Line: https://youtu.be/REz5xpQgWBs

A Line Combined With Two Cartoning Machines & labeler: https://youtu.be/t8PvgrvGNxY

Alu-PVC-Alu Blister Packaging Machine: https://youtu.be/tLGrvvusSjM

Intermittent Cartoner for package of bottle: https://youtu.be/6rkmsE3BGNE

Continuous motion Blister Line in pharma: https://youtu.be/27k-WVXdZ94

Cartoner ZH150 connect with Stretch banding Machine: https://youtu.be/fgqfWoIkOkw

Capsule orienting & feeding device: https://youtu.be/FKCNDLNSG-A

A Line Combined With Two Cartoning Machines: https://youtu.be/aZEvcZuJSE8

Blister Packaging line in pharma: https://youtu.be/TcDaQuNjd3Y

Continuous motion Blister Machine and Cartoning Machine: https://youtu.be/mcDc_qjXUG4

A line intergrated Labeller Blister Machine & Cartoner: https://youtu.be/O8-jZ9c_S4k

Continuous Motion Cartoning Machine: https://youtu.be/zOz57NT6c10

Strip Packing combined with Cartoning Machine: https://youtu.be/gGsWc9Ec6wY

Cartoning Machine for tube packaging: https://youtu.be/-x4YqHxGq_Q

Cartoning Machine in Ukraine: https://youtu.be/_V77djrV8sw

Blister Machine in Thailand: https://youtu.be/TBg5fmbiiCc

Cartoning Machine for tube: https://youtu.be/59IliRn99UM

High speed Blister Machine in pharma: https://youtu.be/F-xuqMcPRmY

Cartoning Machine for packaging of bottle in Thailand: https://youtu.be/N0bgPGGPfII

Intermittent Cartoning Machine running in pharma: https://youtu.be/8ogHSMV-obQ

Continuous motion Blister Packaging Line in pharma: https://youtu.be/OFJ464gGWAY

Cartoning Machine ZH220 in production in pharma: https://youtu.be/CA3HzQ65EFU

Blister Machine DPH350 pharmaceutical company: https://youtu.be/roNLNNtVZ4Y

Blister Line 300 for a customer from Pakistan: https://youtu.be/HyCCb6TmYj8

Ampoules Blister Line equipped a robot feeders in Europe: https://youtu.be/fpUunpDxQXQ

Blister Packaging Line in Pakistan: https://youtu.be/dzAh0lAaUOs

Alu-pvc-alu Blister Packaging Line in Pakistan: https://youtu.be/hnDD1JWeTXQ

Blister Machine and Cartoning Machine in Europe: https://youtu.be/bZ5L8wFVYxM

Ampoules & vials Blister Packaging Line in Turkey: https://youtu.be/EewVyXW73GM

Blister Packaging Line in Kanejia Pharma Group: https://youtu.be/kCacFi6R9Xc

Blister Packaging Line in Jinchen Pharma Group China: https://youtu.be/apb_hUzy9-U

Cartoning Machine equipped with a delta robot: https://youtu.be/V6DsMXP-L9Y

Blister Packaging Line in Jiufan pharma: https://youtu.be/rzu4dCAp4rc

DPP150-ZH120 Blister Packagin Line in Russia: https://youtu.be/leNuJmy8vqM

Continuous motion Cartoning Machine in Jiufang Pharma: https://youtu.be/EJYHTsWLTqs

Cartoning Machine in pharmaceutical company: https://youtu.be/VJFIF9gHgS0

Blister Packaging Line in Algeria: https://youtu.be/FdkvZlzlXuE

Solution of stacking 10 blister cards in one carton: https://youtu.be/H6alv4SAjvs

Cartoning Machine for packaging of ampoule: https://youtu.be/OsS5nxefd6s

Cartoning Machine integrated Ampoule Printing Machine: https://youtu.be/G8aS_3BRBp8

Intermittent cartoning machine in production in Russia: https://youtu.be/9AEQsUPN41s

Alu-alu Blister Packaging Machine in production: https://youtu.be/wEkos69bN4A

Blister packaging machine for vials, ampoules in Russia: https://youtu.be/lpRyAQzG4uk

Blister Packaging Line in production: https://youtu.be/yiMnyHqcyYs

Blister Machine, packaging for pharmaceuticals in Thailand: https://youtu.be/NEqjuxyjvTU

Continues motion Cartoning Machine ZH220: https://youtu.be/N_70n0gbu74

-300x300.jpg)

-1-300x300.jpg)