Blister Line BPL500R

The video of this Blister Line:

https://youtu.be/qPvBHUSGFRY

At the expo:

https://youtu.be/8RIkapCdidA

. High-speed, fully servo regulated, the culmination of our more than 30 years of professional experience.

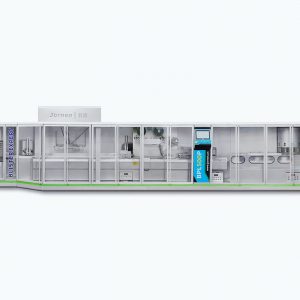

. By integrating a rotary-style blistering and continuous motion cartoning module for packaging of pharmaceutical tablets and capsules, high efficiency and highly flexible, maximum output reaches 500carton/; it is ideal for mass production.

. Processes all common solid dose products and all types of forming material.

. The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module, with forming material reels of up to 600mm in diameter and a waste material trimming cutter.

. Capable of all standard types of closure systems for cartons from tuck-in to hot melt.

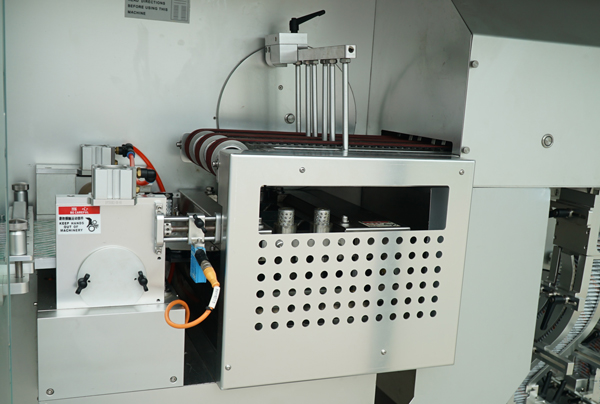

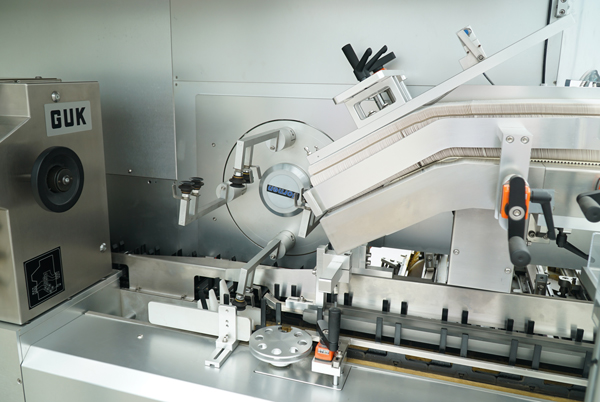

. The heart of a Blister Line is the connection between the Blister module and the Cartoner module. In this line, the connection phase is truly innovative thanks to blister cards pick-up arms, vacuum conveyors, and the blister counting magazines that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to ensure the stability of high running speed.

. GMP-compliant cantilever (balcony type) layout for easy pharmaceutically compliant cleaning.

. In the blister unit, when the first reel’s film runs out in the blister module, it can automatically connect with the second without interruption to the machine (optional).

. The cartoning machine is truly ergonomic thanks to the innovative design whereby the product inserting device is placed at the rear; The conventional cartoning machine’s inserting device is placed at the front side, where it protrudes from the operation side and is less ergonomic.

. The cartoner module is equipped with a servo-regulated robot that can automatically load cartons when the carton magazine is low (optional).

. The blister and cartoner unit were optimally combined in this line, less than 12 meters in length; it provides easy changeover for different sizes of formats and cartons.

. This line adopts the fully-enclosed structure and safety door; it aligns with the stringent safety standards.

See our machines running in the pharmaceutical company.

Max. Output: 500 cartons/min.

Range of Carton Size: Max.: 200x90x60mm Min.: 75x35x15mm

Machine Power: 47kw

Machine Dimension: 1150x1800x2100mm

Machine Weight: 7600kg

-300x300.jpg)

-300x300.jpg)