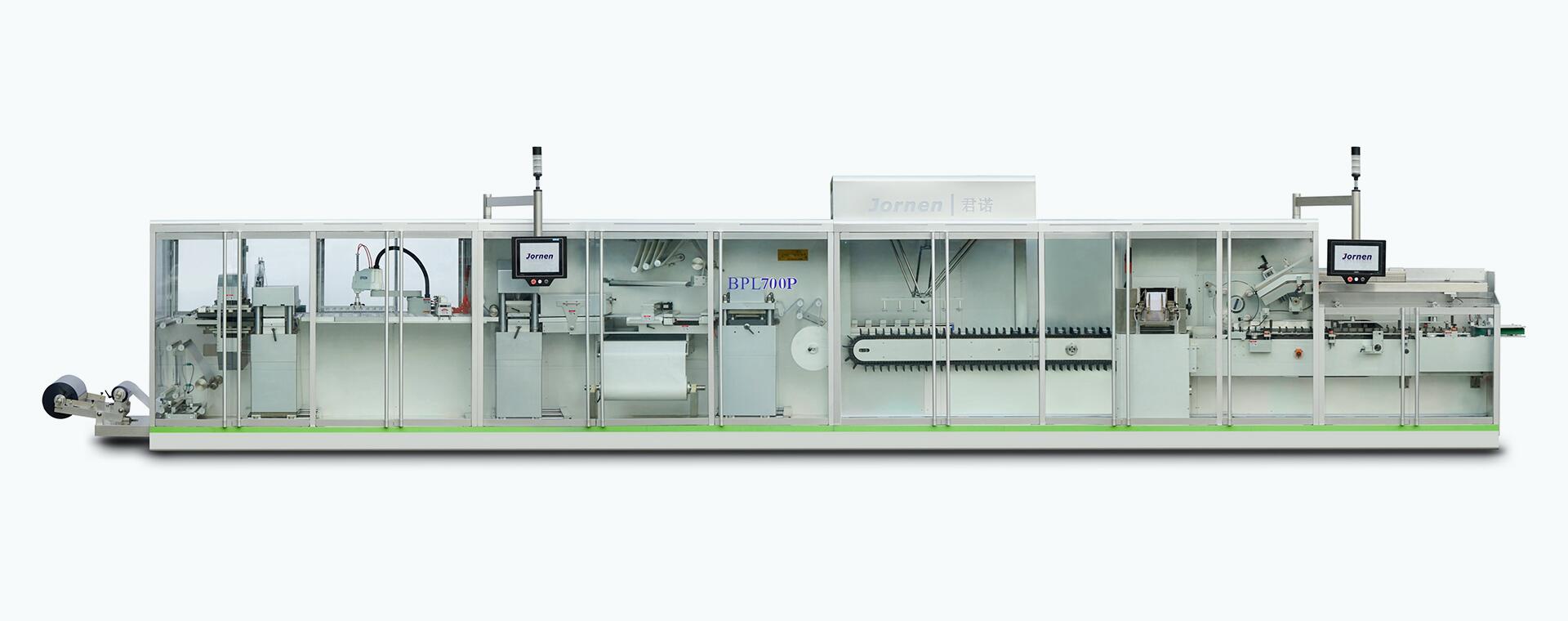

Blister Line BPL700 (for parenteral products)

BPL700 blister packaging line designed explicitly for parenteral products. The blister packaging machine’s PVC boasts an impressive width of 700mm, enabling it to form a large area quickly. The machine’s independent servo motor drives each station, making it adaptable to changing product varieties.

The design of the packaging layout of the blister card can be customer-made; in this demo blister line, the blister card contains one syringe and vial. This design would allow medical staff to use the prefilled syringes and vials immediately at the emergency site, saving lives in critical situations.

A fully automatic servo robot feeds both the syringe and the vial. The syringes can be poured into the bin at will, automatically sorted into rows by the system, and transported to the servo robot.

The design is optimized for ergonomic comfort in the sealing process, with the lidding material positioned low for effortless material replacement.

The blister line’s connection unit uses a servo conveyor belt to grab the blister cards and transport them to the cartoning machine. The connection unit has a compact structure, saving valuable space. The Blister Line adopts a continuous motion cartoning machine that can implement tuck-in or hot-melt closure on the carton according to customer requirements.

To witness the blister line in action, click the provided link to view the video.

https://youtu.be/wa2nOdbdbi8

Max. Output: 500 cartons/min.

Material: Max. width 700mm

Range of Carton Size: Max.: 200x90x60mm Min.: 75x35x15mm

Machine Power: 30kw

Machine Dimension: 1210x2350x2130mm

Machine Weight: 11000kg

-1-300x300.jpg)