Blister Line BPL120

The video of this line: https://youtu.be/EdFXkFpHK8I

These days, pharmaceutical packaging systems must fulfill this market requirement: the volumes of batches are decreasing and the number of variations is increasing, which leads to frequent format change-overs and cleaning.

This Blister Line is our latest innovative response to this market need.

. Integrating Blister Packaging and Cartoning systems achieves high efficiency and low-cost operation.

. Flexible and straightforward for multi-variety and small batch production.

. Optimally combined to form a compact line only seven meters long, enabling installation in small production space.

. Central operation via touch-screen system.

. After filling, a color camera subsequently checks the products – it can reject faulty blisters automatically (optional).

. When the machine stops, the heat sealing mold can rise up automatically to prevent hot air from getting into the blister pockets, preserving medicine effectiveness.

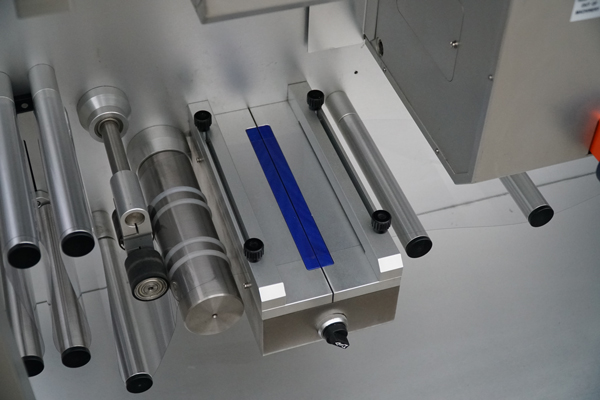

. The index system uses a precise servo motor for stable, accurate running. The blister length can be set freely through the Touch Screen User Interface, which reduces the time for a format changeover.

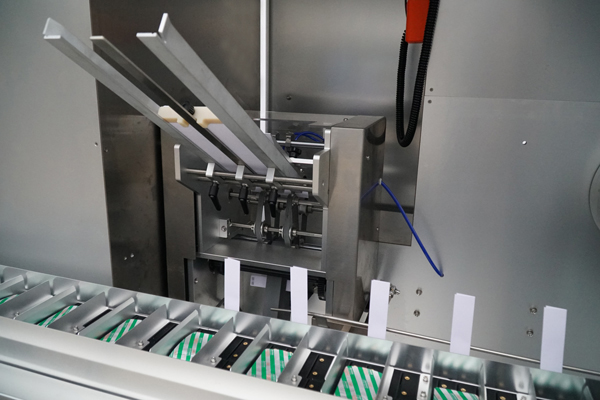

. The blister transfer mechanism uses suction arms, takes the blister cards from the punch station, and gently forwards them to the blister magazine.

. The blister magazine in the cartoner unit is carried out by a servo motor. Inside the magazine, the blister cards are counted and, when they free fall, are held in position by the transfer belt.

. The leaflets are isolated from the bottom of a pile magazine, then pulled off and folded. According to the customer’s requirements, leaflets can be folded from one to four folds.

. If there are no cartons and/or blister cards, the leaflet folder will automatically be suspended without stopping the machine – a new leaflet is then ready to be inserted in the good carton.

. The inserter device can push the blister cards and leaflets into the carton.

. In the carton conveyor chain, the cartons are closed automatically. By using the digital position indicator, straightforward adjustments are achieved

. The carton closing station is for tuck-in, and the hot-melt unit can also be integrated into the cartoner.

. Thanks to its toolless size-changing the machine production times are increased and the machine idle times are reduced.

. The Blister Line adopts a transparent cover which assures safe operation.

See our machines’ performance in the pharmaceutical company.

-1-300x300.jpg)

-300x300.jpg)